Tech Tip: Fixing A Loose Exhaust Pipe Spigot (Triumph Twin)

Today I will be covering a new Tech Tip post in regards to a loose exhaust pipe spigot adapter based on a recent experience

Should you have encountered a problem in which your spigot came loose in your cylinder head, perhaps my fix will be valuable to you

Keep reading below...

What happened?

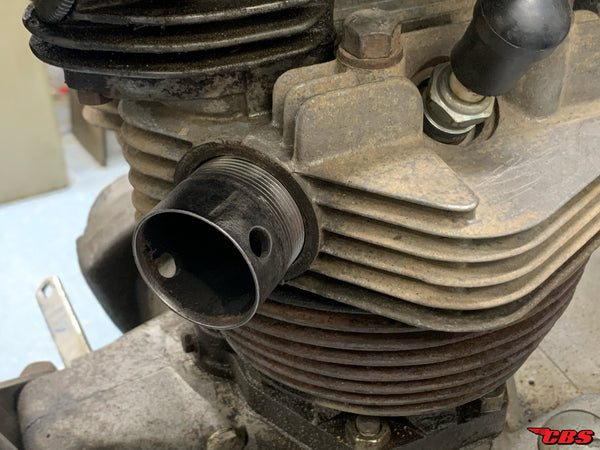

Over the weekend I removed both my exhaust pipes on my “Trusty Rusty” 1968 Triumph TR6R only to find that exhaust port #2 spigot had worked loose

As I was “wiggling” the exhaust pipe off, I noticed that the spigot was moving in the same direction as the header pipe

For those that have encountered a “loose spigot” in your cylinder head, I’m sure you know that feeling you get; an instant drop in your mood as you begin to check for damage

For this particular situation I remained confident as my pipes, mufflers and brackets always remained tight and secure which prevents damage from occurring

The discovery

Once my exhaust pipe was removed, I unthreaded the spigot and checked the quality of the threads for any damage

What I saw was not alarming by any means..

Since the pipes were off, I checked the exhaust pipes and found that the exhaust was burning rather nice - no oil residue which was nice too see (although I was not experiencing any burning oil issues to begin with…)

I cleaned both the spigot and cylinder head threads off with carb cleaner and a brush to begin a thorough inspection

Couple problems

Loose exhaust spigots plague vintage Triumphs, most can be fixed quickly on the bike and some require an oversized spigot or that the head be removed and then bored and re-tapped on a mill

I threaded my exhaust spigot into the port and noticed some “slop” from the adapter

Depending on the machine work and tolerances, the “slop” or “play” I felt could be how it was from the factory or simply because the spigot and or head had some wear

The second problem I found which I believe is the reason the spigot came loose is that the spigot was not properly seating on the shoulder inside the port

In fact, looking inside the port with a mirror I found that the spigot was indeed too short to begin with..

For this particular case, I needed to make a longer spigot, and also improve on the thread engagement

Why spigots work loose

Let’s take a look a little deeper as to why spigots come loose

Pictured is an original triumph exhaust pipe spigot, notice that the very end (arrow) shows an undercut, that is to allow the spigot to fully thread in the exhaust port and bypass the bottom taper cut into the threads by a tap

When a Triumph cylinder head was machined, the factory used a “bottoming” tap which has a few tapered and non-formed threads (see above photo)

That “taper” or portion with a lack of threads is exactly why the spigot needs to have an undercut to be able to pass the tapered threads and meet / bottom out with the shoulder face to get the maximum load on each thread

Also, when the spigot is not made to the proper length or feature the correct undercut the spigot could bottom out on the tapered threads internally or stop at at the end of the spigot due to a lack of thread reach

Mind you that installing “new” spigots may not fix your problem as each head is machined slightly different - some may have deeper ports which require a longer spigot

3 key elements to achieve a tight spigot

There are 3 major factors you need to know to help achieve a tight spigot that will not back out

- Undercut at the beginning of the threads

- Spigot must be the right length

- Good thread engagement

If you have all 3 factors above, then you should be able to achieve a tight spigot that will not come out under normal riding conditions

Fixing my problem

As I explained my problem and why spigots work loose, I came to the conclusion that I would have to make my own spigot for exhaust port #2

My “off the shelf” spigots are the same as my original that came out of the head which will not help me address the current issue at hand

Below I will go over my solution..

Step #1 - Measuring depth

I grabbed my Starret depth micrometer and measured how deep the shoulder is to the face of the head

The outside face will be parallel to the shoulder face inside the port

Doing this measurement will inform me of how long I need to make the spigot and how long the threads need to be cut on the spigot

In this particular instance the depth is .877” which is close to 7/8”

Step #2 - Making the spigot

Now that we have the depth recorded, we must get ready to cut threads

The stock I’ll be using is 1018 steel hollow tube that will need to be machined in the ACRA lathe

We will machine the spigot with a goal of 5 dimensions we must achieve

- 1 5/8” OD for threads

- 1.650” OD for exhaust pipe cup

- 3/4" for the spigot length protrusion (outside the head)

- 1 3/8” ID

- 16 TPI

Once done with turning, boring and cutting threads we will bore (2) 1/2” holes inline on my mill to accept my installation tool that I will show further below..

Step #3 - Checking contact

Now that the spigot is ready to rock-and-roll, I like to check that the spigot is making contact with the shoulder inside the port before locking the spigot in place

You can use dye, sharpy or rely on the carbon to view any rubbing or witness marks

In this case we used the carbon residue

If the spigot is not making contact and the length is correct, go to the lathe an add either a deeper undercut or wider undercut to get pass the tapered threads we talked about earlier

Step #4 - Installation

Taking the time clean all surfaces and threads, I add a little bit of anti-seize to prevent any gauling or seizing of the spigot

I then use my custom spigot “heavy duty” installation tool to lock the spigot in place

The tool I designed allows me to really torque down on the spigot using an 1 1/4” wrench

There is a 3/8” OD hardened and ground pin that slides through the tool and spigot to drive the spigot

FYI - some folks have recommended to use green Loctite bearing retainer. I do understand that loctite does have a heat threshold, but a little loctite doesn’t do any harm for added security should it make you feel more comfortable

Work is complete

Here is the new spigot in the cylinder head ready to go

Based off how tight the spigot is in the head (along with the good contact area) this spigot will not back-out under any application and I will consider it a permanent fix

I hope this post will help someone along the way

Thanks for reading

Thanks for reading todays post

Click here for more blog posts like this one

Should you have any questions, please drop us a comment using the comment section below

Ride safe!

dale mogenson

great information from a trusted source for all the issues that crop up in maintaining our tr’s.

Dave Smith

A fine article indeed. Keep ’em coming! I see that your relatively thick wall spigot will cause a sudden “step change” in the ID of the tube as the exhaust enters the larger ID exhaust pipe. I wonder if you were to make a gradual taper-cut in the ID near the output of the spigot, and taper the ID to become relatively thin at the output, would the exhaust benefit from less turbulence and a more laminar flow?

Classic British Spares

@Floyd – Thank you!

@John – Worth a shot! Thanks for reading today John

@Meli – Exactly! Thanks for reading and commenting

@Craig – Yes that is a good fix that appear to work. I have seen others do the same. Thanks for reading and commenting!

Floyd Kehl

I like eliminating the first thread and a half, slathering with anti-seize and running it home with your tool.

John

People tell me that if you aren’t a skilled machinist, high temperature JBWeld also solves the problem, for a while anyway.